We currently have PEM PTL production in our plants in Belgium, China and Japan.

We also have a dedicated R&D facility in Belgium: the Hydrogen Technology Center.

Hydrogen generation is a fast growing market, requesting timely and qualitative supply of PTL and/or information.

Hence questions may arise on various subjects which we envisage to tackle here.

Where are your products manufactured?

We currently have PEM PTL production in our plants in Belgium, China and Japan.

We also have a dedicated R&D facility in Belgium: the Hydrogen Technology Center.

What is the new name of the materials I have ordered in the past?

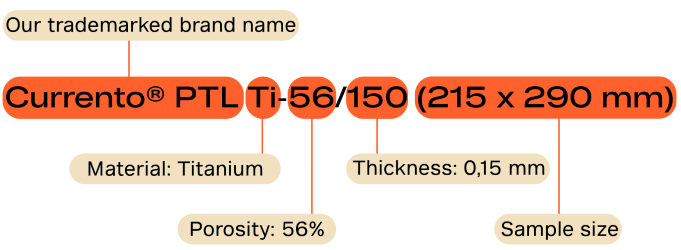

We've changed our material codes in 2024. If you're looking for the old material codes, you can find them in this table, together with the new material codes.

You can request a quote on our website.

| Material Code (before 2024) | Material Code (2024) | Thickness | Thickness | Porosity | Surface Area | |

|---|---|---|---|---|---|---|

| Currento® 2NI 06-0,100 | Currento® PTL Ni-66/100 (215 x 290 mm) | 0,10 mm | 0.004 inch | 66% | Normal | |

| Currento® PTL Ni-66/100 (430 x 580 mm) | ||||||

| Currento® 2NI 06-0,200 | Currento® PTL Ni-83/200 (215 x 290 mm) | 0,20 mm | 0.008 inch | 83% | ||

| Currento® PTL Ni-83/200 (430 x 580 mm) | ||||||

| Currento® 2NI 18-0,250 | Currento® PTL Ni-60/250 (215 x 290 mm) | 0,25 mm | 0.010 inch | 60% | ||

| Currento® PTL Ni-60/250 (430 x 580 mm) | ||||||

| Currento® 2NI 30-0,500 | Currento® PTL Ni-66/500 (215 x 290 mm) | 0,50 mm | 0.020 inch | 66% | ||

| Currento® PTL Ni-66/500 (430 x 580 mm) | ||||||

| Currento® 2NI 18-0,500 | Currento® PTL Ni-80/500 (215 x 290 mm) | 80% | ||||

| Currento® PTL Ni-80/500 (430 x 580 mm) | ||||||

| Currento® 2NI 30-1,000 | Currento® PTL Ni-83/1000 (215 x 290 mm) | 1,00 mm | 0.039 inch | 83% | ||

| Currento® PTL Ni-83/1000 (430 x 580 mm) | ||||||

| - | Currento® PTL INC 79/600 (210 x 297 mm) | 0,60 mm | 0.024 inch | 79% | Medium | |

| Currento® PTL INC 79/600 (430 x 580 mm) | ||||||

| - | Currento® PTL NI HR 78/300 (210 x 297 mm) | 0,30 mm | 0.012 inch | 78% | High | |

| Currento® PTL NI HR 78/300 (430 x 580 mm) | ||||||

| - | Currento® PTL NI HR 82/500 (210 x 297 mm) | 0,50 mm | 0.020 inch | 82% | ||

| Currento® PTL NI HR 82/500 (430 x 580 mm) | ||||||

| - | Currento® PTL INC 82/500 (210 x 297 mm) | |||||

| Currento® PTL INC 82/500 (430 x 580 mm) | ||||||

| Currento® 60 BL3 | Currento® PTL SS-74/145 (210 x 297 mm) | 0,15 mm | 0.006 inch | 74% | Normal | |

| Currento® PTL SS-74/145 (430 x 580 mm) | ||||||

| - | Currento® PTL SS-85/1000 (210 x 297 mm) | 1,00 mm | 0.039 inch | 85% | ||

| Currento® PTL SS-85/1000 (430 x 580 mm) | ||||||

| Currento® 20 AL3 | Currento® PTL SS-82/500 (210 x 297 mm) | 0,50 mm | 0.020 inch | 82% | Medium | |

| Currento® PTL SS-82/500 (430 x 580 mm) | ||||||

| Currento® 10 BL3 | Currento® PTL SS-81/200 (210 x 297 mm) | 0,20 mm | 0.008 inch | 81% | High | |

| Currento® PTL SS-81/200 (430 x 580 mm) | ||||||

| Currento® 10 FP3 | Currento® PTL SS-71/260 (210 x 297 mm) | 0,26 mm | 0.010 inch | 71% | ||

| Currento® PTL SS-71/260 (430 x 580 mm) | ||||||

| Currento® 10 AL3 | Currento® PTL SS-78/300 (210 x 297 mm) | 0,30 mm | 0.012 inch | 78% | ||

| Currento® PTL SS-78/300 (430 x 580 mm) | ||||||

| - | Currento® PTL SS-62/410 (210 x 297 mm) | 0,41 mm | 0.016 inch | 62% | ||

| Currento® PTL SS-62/410 (430 x 580 mm) | ||||||

| Currento® 2GDL6-0,150 | Currento® PTL Ti-56/150 (215 x 290 mm) | 0,15 mm | 0.006 inch | 56% | Normal | |

| Currento® PTL Ti-56/150 (430 x 580 mm) | ||||||

| Currento® 2GDL10-0,250 | Currento® PTL Ti-56/250 (215 x 290 mm) | 0,25 mm | 0.010 inch | |||

| Currento® PTL Ti-56/250 (430 x 580 mm) | ||||||

| Currento® 2GDL20-0,500 | Currento® PTL Ti-56/500 (215 x 290 mm) | 0,50 mm | 0.020 inch | |||

| Currento® PTL Ti-56/500 (430 x 580 mm) | ||||||

| Currento® 2GDL20-1,000 | Currento® PTL Ti-56/1000 (215 x 290 mm) | 1,00 mm | 0.039 inch | |||

| Currento® PTL Ti-56/1000 (430 x 580 mm) | ||||||

| - | Currento® PTL Ti-66/200 (215 x 290 mm) | 0,20 mm | 0.008 inch | 66% | ||

| Currento® PTL Ti-66/200 (430 x 580 mm) | ||||||

| - | Currento® PTL Ti-67/200 (215 x 290 mm) | 0,20 mm | 0.008 inch | 67% | ||

| Currento® PTL Ti-67/200 (430 x 580 mm) | ||||||

| - | Currento® PTL Ti-68/350 (215 x 290 mm) | 0,35 mm | 0.014 inch | 68% | ||

| Currento® PTL Ti-68/350 (430 x 580 mm) | ||||||

| - | Currento® PTL Ti-70/750 (215 x 290 mm) | 0,75 mm | 0.030 inch | 70% | ||

| Currento® PTL Ti-70/750 (430 x 580 mm) | ||||||

| - | Currento® PTL Ti-77/2000 (215 x 290 mm) | 2,00 mm | 0.079 inch | 77% | ||

| Currento® PTL Ti-77/2000 (430 x 580 mm) | ||||||

| - | Currento® PTL Ti-78/2000 (215 x 290 mm) | 2,00 mm | 0.079 inch | 78% | ||

| Currento® PTL Ti-78/2000 (430 x 580 mm) | ||||||

| No separate material code existed | Currento® PTL Ti-56/150 PT200 (220 x 290 mm) | 0,15 mm | 0.006 inch | 56% | Normal | |

| Currento® PTL Ti-56/150 PT200 (440 x 550 mm) | ||||||

| Currento® PTL Ti-56/250 PT200 (220 x 290 mm) | 0,25 mm | 0.010 inch | ||||

| Currento® PTL Ti-56/250 PT200 (440 x 550 mm) | ||||||

| Currento® PTL Ti-56/500 PT200 (220 x 290 mm) | 0,50 mm | 0.020 inch | ||||

| Currento® PTL Ti-56/500 PT200 (440 x 550 mm) |

What are lead times for sample shipments?

Our lead times are 3 weeks for materials we have available on stock.

How fast can you scale? What is your capacity?

Driven by the opportunities arising from the energy transition and decarbonization trends, Bekaert accelerates its growth strategy in renewable energy markets, particularly in green hydrogen production.

As part of this strategy, Bekaert announced on 17 April 2023 the investments it is making in Belgium, to expand its manufacturing and research capacity in electrolysis technologies for green hydrogen production.

These investments include:

We also have over 20 years of experience producing PEM PTL's in Japan, at a capacity of 0.2 GW and since 2023 in China, at a capacity of 1 GW.

Currently, we're also working on finding the right location for our giga-factory for electrolyzer components, with a planned capacity of 5 GW.

Can you explain your product codes?

What is your VAT ID number and D-U-N-S Number?

VAT ID = BE 0405.388.536 RPR Kortrijk

D-U-N-S number = 370513848

Do your products have a top and bottom side?

Our monolayer materials do not have a top and bottom side.

Our dual layer materials have a fine toplayer (usually facing the MEA/CCM side) and a coarse backlayer (facing the Bipolar Plate side).

Where can I find Bekaert’s certifications and policies?

Bekaert’s corporate policies, Code of Conduct, and ISO certifications are publicly available on our Policies page. This includes ISO certificates that cover multiple production sites, including those from which we supply our porous transport layers (PTLs).

Please note that Bekaert Taicang Metal Fiber (BTMF) is not a fully owned subsidiary and is therefore not included in the group ISO certificate.

What are your sales terms and conditions?

You can find the general terms of sale in your language on our website.

How can I get a quotation for non-standard products?

Reach out to us via the contact form on our website.

Can I get in touch with a local sales office?

We've made it easy to request a quote or to ask a question on our website.

If you need to ask a specific question, we have colleagues in several local sales offices worldwide: North America, EMEA, Japan, China, India and Korea. You'll be able to reach them via the Contact form.

Is there a Safety Data Sheet (SDS) available?

We have no Safety Data Sheet available. Our products are not chemicals but articles. REACH explicitly defines that SDS is relevant to chemicals only, and legal authorities recommend not to issue SDS's for articles.

Reach us via our contact form and get easily redirected to the person who can help you.