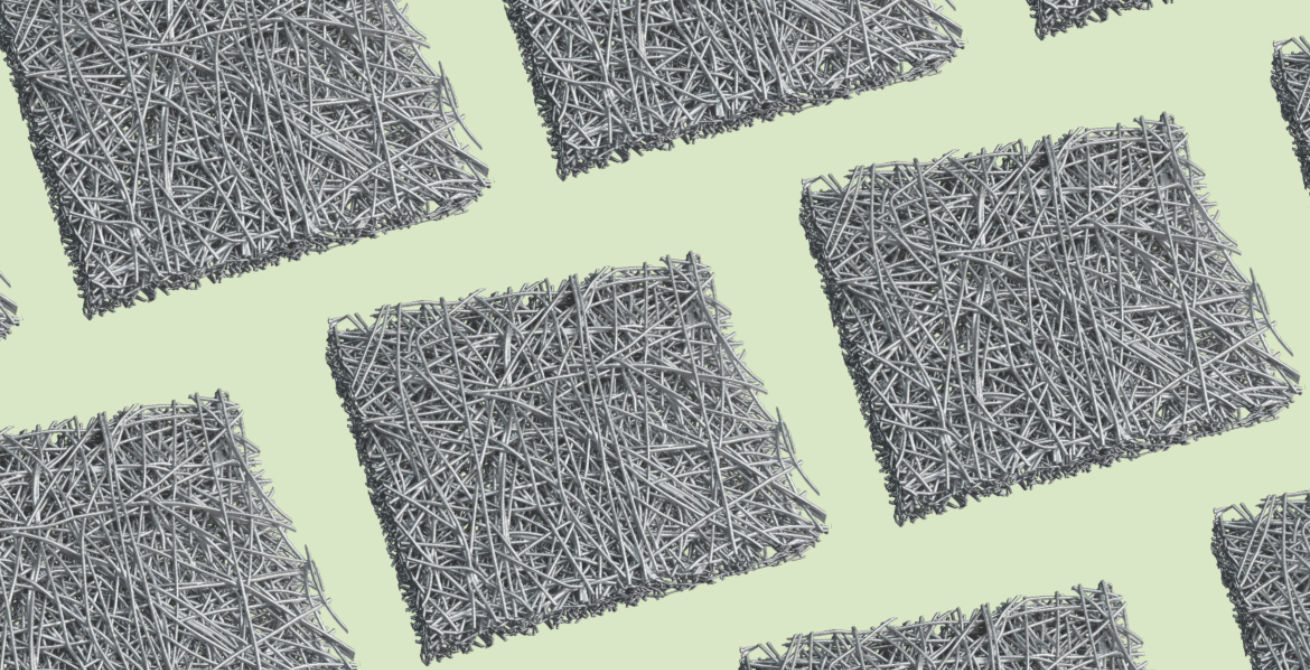

Nickel is corrosion-resistant in alkaline environments and offers excellent conductivity at a lower cost than noble metals.

Anion Exchange Membrane Electrolysis

Anion Exchange Membranes (AEM) offer an alternative method of hydrogen electrolysis. AEM electrolysis uses a water splitting reaction to separate hydrogen and oxygen gases. The membrane is permeable to hydroxide ions. Though high pH-values favor the hydroxide transport through the membrane, neutral pH values significantly reduce corrosion. In AEM development, neutral pH values are one of the long-term targets. By using pure or slightly alkaline solutions as an electrolyte the risk of leakage and corrosion is further reduced. And while this technology undergoes development, it has potential to produce green hydrogen from renewable energy at lower LCOH.