It offers high efficiency and compact design, suitable for mobility and industrial use.

Proton Exchange Membrane Electrolysis

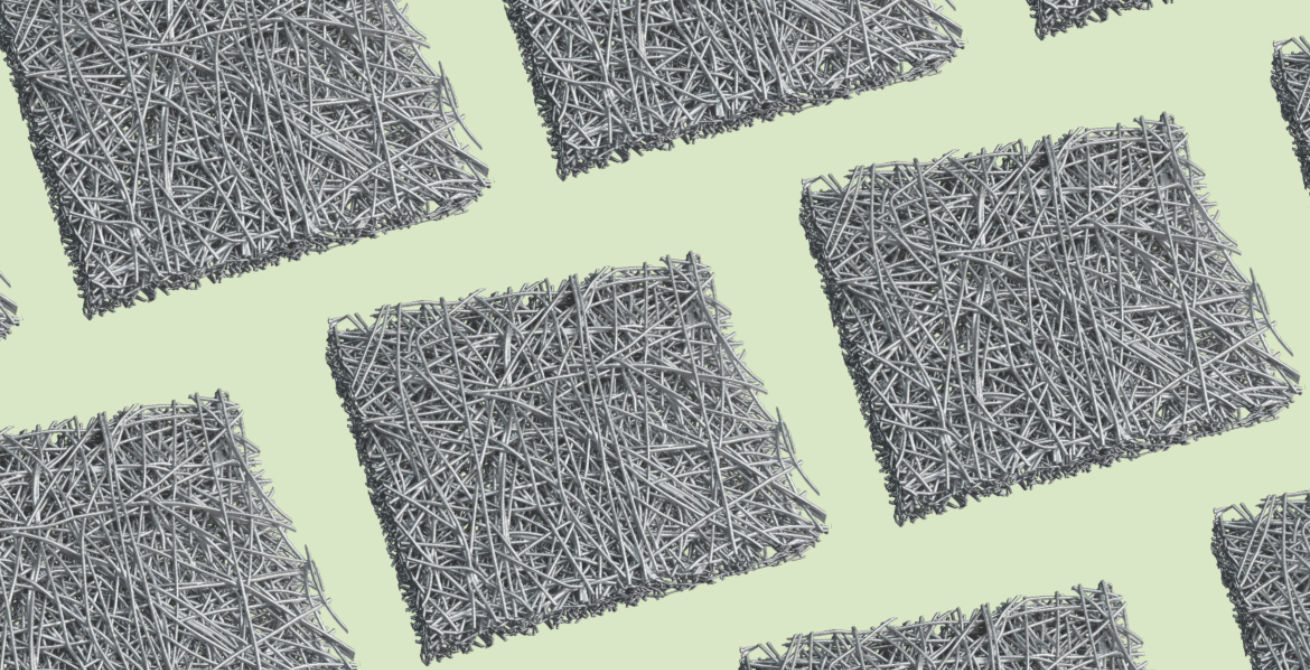

Proton Exchange Membranes (PEM) are a thin polymer electrolyte membrane. It's used in fuel cells and electrolyzers to conduct positively charged hydrogen ions or protons, producing water and hydrogen as byproducts. The PEM separates the anode from the cathode. This allows hydrogen ions to flow from the anode to the cathode through the membrane. Electrons provide an electrical current as they flow through an external circuit.

PEM is widely used in transportation, stationary power generation, and portable power applications.