For Your Research and Design Success

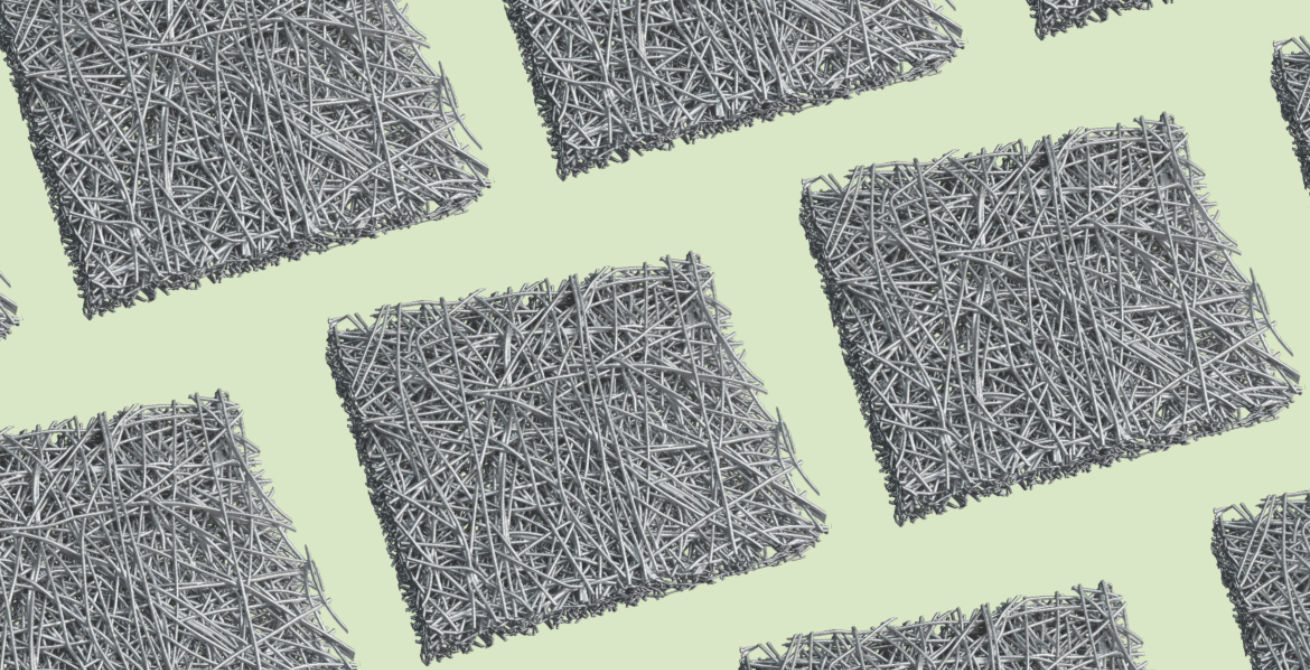

The hydrogen production process uses electrolyzer technology to split water into hydrogen and oxygen. There are several types of hydrogen electrolyzer designs in use today. Operating conditions and electrolyte materials are a few variables that dictate design. And, depending on the design, electrolyzers can utilize a variety of sustainable energy sources and more.