You can cut our materials via laser cutting with the required safety measures to prevent fires. Mechanical cutting is possible if the tolerances can meet your requirements.

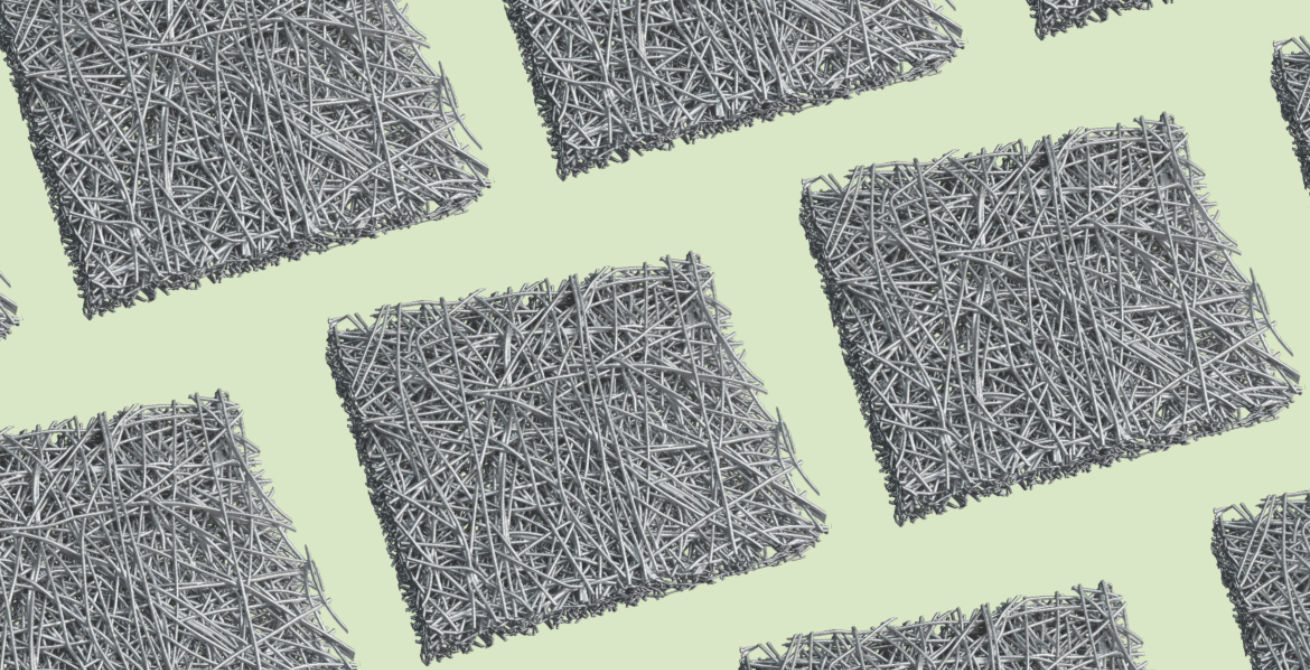

Green hydrogen starts with smart materials. At the core of hydrogen production is a component often overlooked, yet absolutely critical: the Porous Transport Layer (PTL). In PEM and AEM electrolyzers, the PTL sits between the catalyst layer and the flow field. This porous, metallic structure plays a pivotal role in optimizing the performance, efficiency, and durability of the electrolyzer. A high-performance PTL supports efficient water electrolysis by:

- Facilitating mass transfer of water and oxygen

- Providing thermal management across the cell

- Providing electrical conductivity across the cell

- Acting as a corrosion resistant mechanical support

As electrolyzer technology evolves, so do the demands. But different electrolyzer chemistries require different PTL materials. PEM Electrolyzers are acidic and oxidative, and typically use titanium.