Proton exchange membrane water electrolysis (PEMWE) is a leading technology for producing hydrogen and oxygen from water using electricity. While still in development, PEMWE systems have already been deployed at the megawatt scale. A PEMWE stack is made up of several single cells. Each cell contains key components platinum group metal (PGM) catalysts (at the anode and cathode), titanium-based porous transport layers, and bipolar plates.

Together, the membrane and catalyst layers form the membrane electrode assembly (MEA) - also known as the catalyst-coated membrane (CCM). Despite its potential, PEMWE faces two main challenges: the high cost of components (CAPEX), and the need for long-term durability and performance (OPEX).

One major cost driver is the use of PGMs—specifically iridium (at the anode) and platinum (at the cathode). These materials are expensive, limited in supply, and associated with a high CO₂ footprint. Iridium, in particular, is scarce, with only 7–8 tons produced globally each year, primarily as a byproduct of platinum mining.

But the high reliance on PGMs in PEMWE is about to change. To accelerate clean hydrogen production, Belgium-based NV Bekaert SA has partnered with Toshiba Energy Systems and Solutions Corporation. Together, they aim to scale the production of ultra-low iridium MEAs and help reshape the global electrolyzer market. Toshiba’s advanced MEA technology marks a major step forward, dramatically reducing the iridium content required in PEMWE systems – without compromising performance.

Since signing a technology agreement in February 2024, Bekaert and Toshiba have been working to combine their respective strengths in technology, manufacturing, and commercialization. As part of the collaboration, Bekaert will industrialize the manufacturing of Toshiba’s advanced ACLS MEA materials. This effort builds on Bekaert’s deep expertise in developing and producing PTLs, which act as the substrate for the ultra-low iridium catalyst coating within the MEA. By applying Toshiba’s innovative approach, iridium use can be reduced by up to 90% - making electrolyzers significantly more cost-competitive, sustainable, and far less vulnerable to supply chain disruptions.

But how does it work?

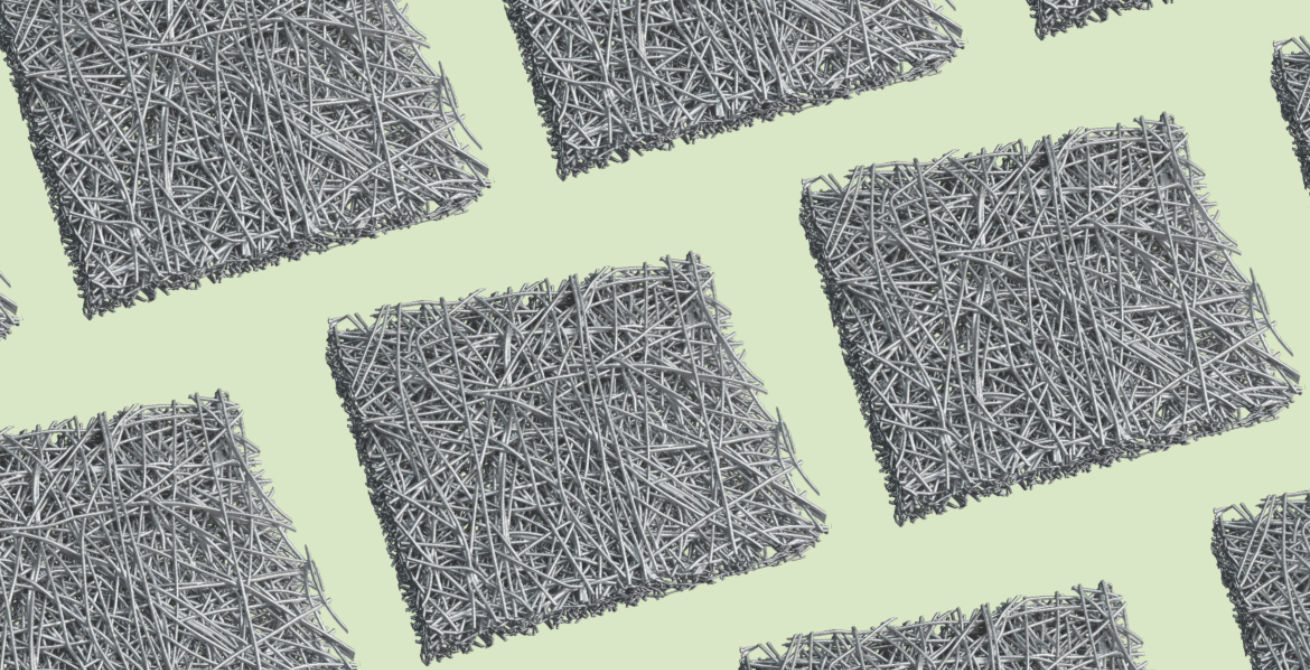

The standard MEA architecture uses catalyst-coated membranes (CCMs), where catalyst inks containing iridium and platinum are applied to either side of the membrane to form the anode and the cathode. Toshiba’s technology, known as Alternating Catalyst Layer System (ACLS), takes a different approach. Rather than coating the membrane, iridium is applied directly onto the PTL to form a porous transport electrode (PTE) - without the need for conventional binder materials.

This method also enables the integration of ultra-thin “nano-sheets.” These self-supported nanostructures offer exceptional catalytic activity and durability. And because these nano-sheets are built directly onto the PTL, rather than the membrane, it allows for extremely low iridium loadings. Without sacrificing performance.

While other low-iridium CCM concepts are still in development, Bekaert and Toshiba consider ACLS a superior solution – especially in terms of performance and durability. ACLS MEA components are currently being produced at both small and medium scale for testing, with large-scale production planned in 2026.

On the road to widespread hydrogen adoption, challenges remain. The global supply chain for critical electrolyzer components, such as PTLs and MEAs, is still underdeveloped. Beyond the limited iridium supply other materials pose challenges related to sustainability, tightening regulations, and supply chain vulnerabilities. Funding continues to lag behind. Mechanisms to close the cost gap between clean hydrogen and fossil-based alternatives, like steam methane reforming (SMR), remain insufficient.

The agreement between Bekaert and Toshiba allows for the scaling of the industrial supply chain behind electrolyzer manufacturing. It lays the groundwork for cost reductions and supports both companies in navigating the ever-evolving energy landscape. As the technology matures, clean hydrogen is expected to become more industrialized and cost competitive, opening the door to decarbonizing a wide range of hard-to-abate sectors.