Not all PTLs are created equal. With so many performance demands, selecting the right PTL material isn’t as simple as selecting something that “works”. Each electrolyzer environment comes with unique challenges. Material decisions have a direct influence on durability, efficiency, and overall cost. A poorly chosen PTL can accelerate degradation of adjacent components, increase system resistance, or introduce reliability issues. For OEMs and system developers aiming to commercialize green hydrogen at scale, PTLs are no place to cut corners. That’s why material innovation is at the heart of the conversation. It’s also where metal fiber PTLs are making their mark.

The case for metal fiber PTLs

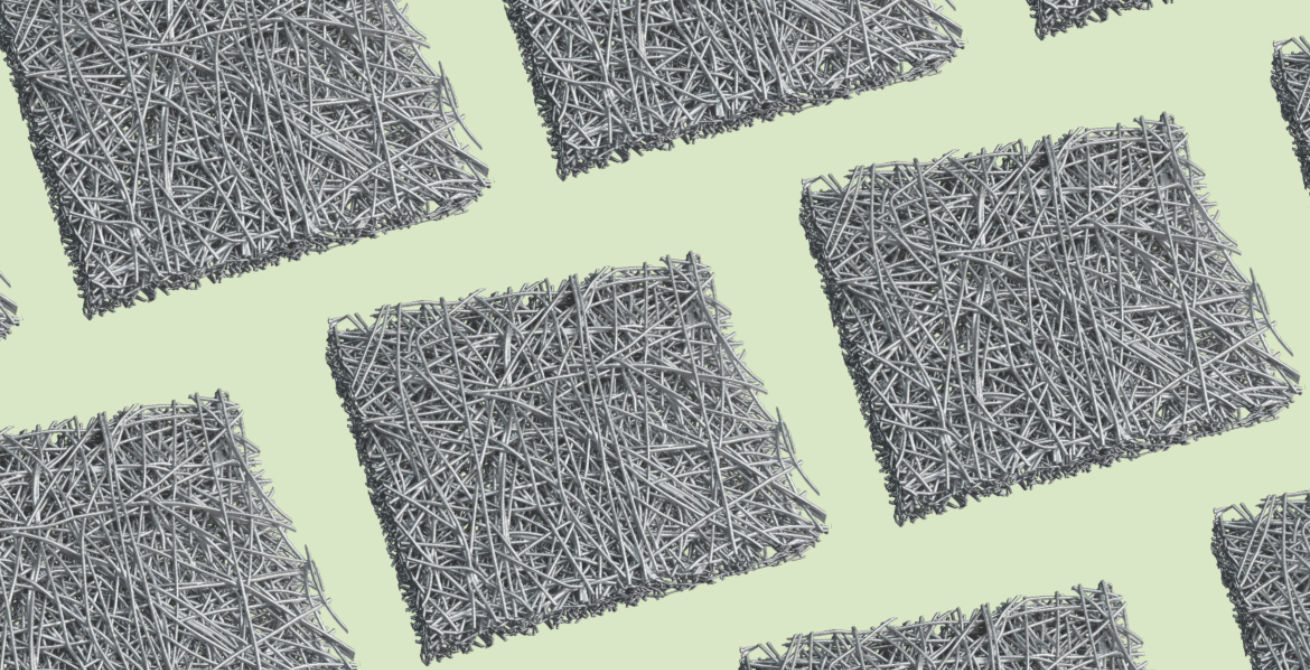

Among the various PTL materials begin developed, metal fibers stand as the frontrunner. They offer high performance and long-term stability that operating stacks require. Unlike flat sheet metals, or other types of PTLs, metal fiber PTLs feature a wide range of porosity without sacrificing strength. This means that they are able to provide optimal mass transfer at a wide range of current densities and withstand high pressures and repeated thermal cycling.

Material-wise, titanium (plain or Pt coated) remains the gold standard for PEM electrolyzers. Although it comes at a higher cost, titanium's inherent corrosion resistance is ideal in acidic conditions. And, for AEM systems, nickel is the most common to offer a reliable solution in the strong alkaline media, while stainless steel provides a cost-effective solution in a milder environment.

The future of hydrogen runs through metal fibers

As the hydrogen economy evolves, the industry is learning that success is in the details. PTLs may not be the most visible component of an electrolyzer stack, but they're foundational to overall performance. In fact, a PTL's ability to balance mass and heat transport, electrical performance, and long-term durability makes them an indispensable component of next-gen green hydrogen systems. With metal fiber PTLs and Bekaert's advanced PTL solutions, stack designers don't have to compromise. They simply select a solution engineered to keep up the pace, and push performance forward. Because, in the grand scheme of things, microns matter.