If you can't find your answer here feel free to get in touch.

1. Why should I add masonry reinforcement?

2. Can I use any type of reinforcement to any type of masonry?

3. How do I adjust Murfor® Compact to the wall width?

4. How do I apply Murfor® Compact?

5. For what applications can I use Murfor® Compact I ?

5.1 stress concentrations

5.2 Long walls

5.3 Point loads

5.4 Partition walls susceptible to deformation

5.5 Stack bonded masonry

5.6 Corner and T-connections

5.7 Laterally loaded wall panels

6. For what applications can I use Murfor® Compact E?

6.1 Stress concentrations

6.2 Long walls

6.3 Gables

6.4 Differential settlements

6.5 Facade support

6.6 Stack bonded masonry

6.7 Laterally loaded wall panels

6.8 Masonry beam design

6.9 Claustra masonry

7. How do I anchor the masonry?

8. How do I place the water retaining membrane?

9. Is Murfor® Compact ETA certified?

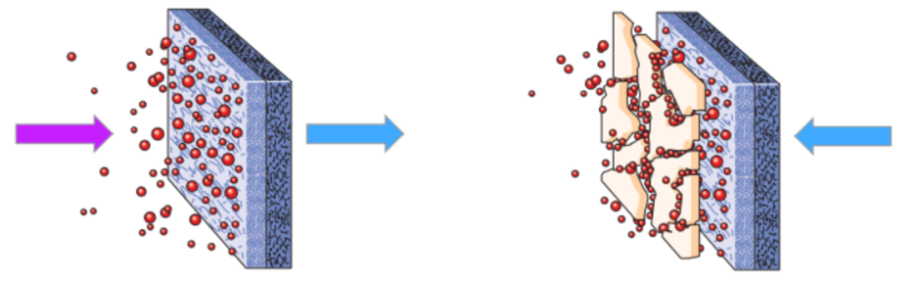

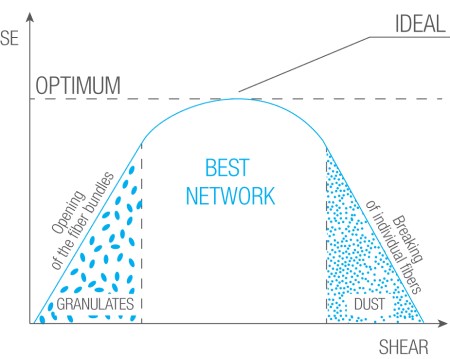

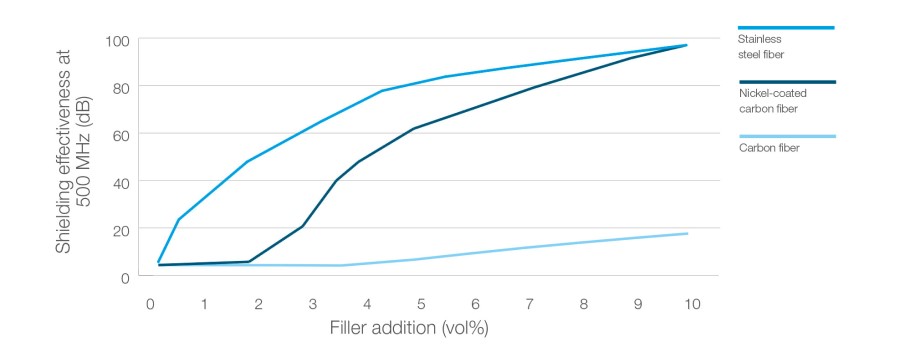

The most important requirement is to make sure that your base polymer is compatible with the polymer coating and/or the sizing of the Beki-shield® grains. Our datasheets provide clear recommendation of which base polymers are compatible with our different types of Beki-shield® grains. The second most important consideration is the processing temperature. This should be in the range defined in the datasheets to make sure that the sizing and/or the coating dissolves correctly. (Depending on the type of product, only sizing will be present, or sizing and coating). This will ensure that all the grains open up easily and disperse well in order to create a good electrically conductive network in the plastic component.