Electromagnetic Interference (EMI) is caused by electromagnetic waves, which can originate from all sorts of different man-made or natural sources (e.g. lightning, power converters, radio antennas, wireless connection, computer clocks, ….). These electromagnetic waves can disturb the proper functioning of sensitive electronic equipment. In some cases, this interference is unacceptable and the correct functioning of your equipment needs to be guaranteed (e.g. anti-collision sensors in a car, EMG equipment, ….). In these cases it is required that a barrier is created in the housing (conductive plastic) which can act as a shield to prevent electromagnetic waves from leaving their source or entering the equipment which needs to be protected.

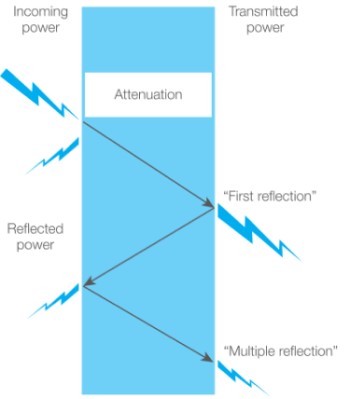

The barrier functions on the principle of the Faraday cage. As shown in the figure below, the Faraday cage will ensure that the power of the incoming wave is reflected and absorbed. By doing so it will reduce the power of the outgoing wave. The shielding effectiveness (SE) of this boundary is a clear indication of how well the boundary can reduce the incoming power of the electromagnetic wave. The higher the SE, the better the boundary will prevent electromagnetic waves from leaving their source or from entering the electrical device.

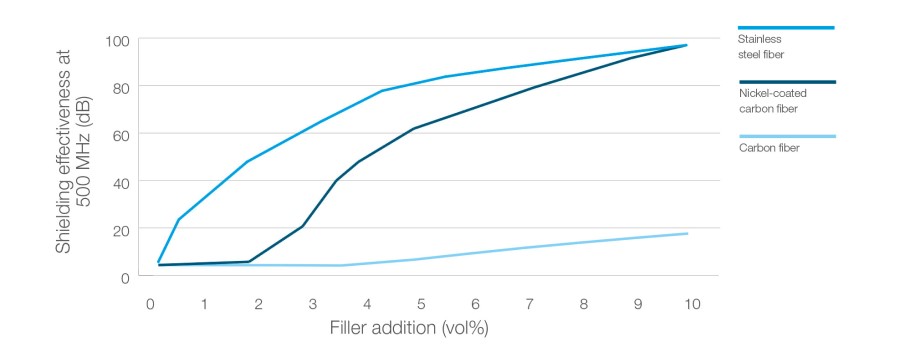

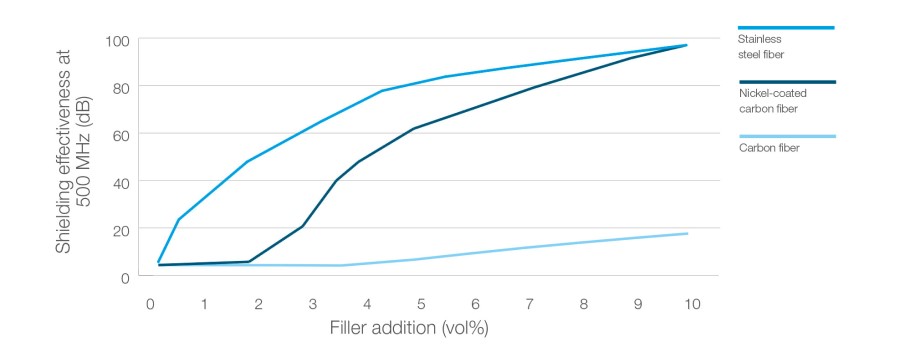

Shielding effectiveness is determined by the frequency, the distance from the source, the type of electromagnetic field (near or far field), the magnetic permeability, the electrical conductivity and the thickness of the boundary. The stainless steel fibers of the Beki-shield® product will make sure that the plastic housing of your electronic equipment reaches extremely high levels of electrical conductivity and thus high levels of shielding effectiveness at very low load levels. This is shown in the figure below, which compares nickel-coated carbon fiber, carbon fiber and Beki-shield®. Our white paper goes into more detail on the exact functioning of EMI shielding and how Beki-shield® provides the highest shielding effectiveness possible.