To some, PEM electrolysis may feel like modern technology. But its roots actually stretch back more than half a century and are closely tied to outer space. With its crucial role in today’s green hydrogen ambitions, the history of PEM spans from laboratory curiosity to spaceflight enabler and beyond. And while space exploration pushed performance demands, it fundamentally shaped PEM into the technology currently in use.

What is PEM?

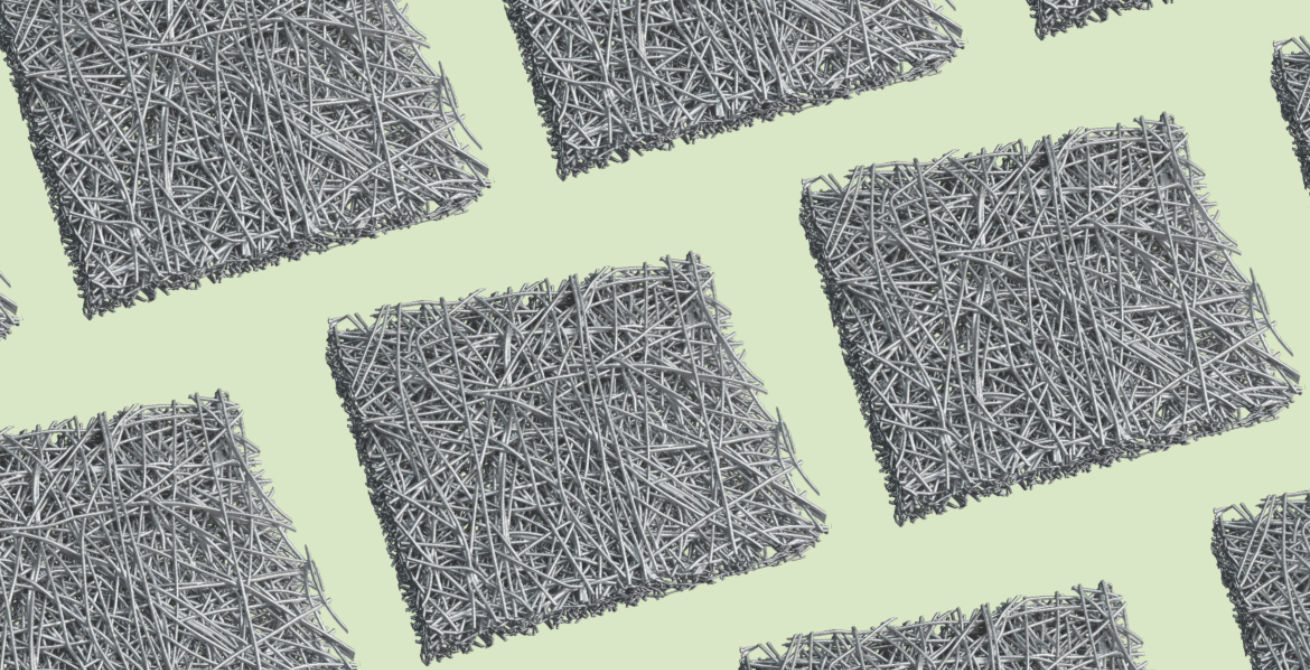

Proton Exchange Membrane, or PEM, is a thin solid polymer layer that sits in the middle of an electrolyzer stack (between the anode and cathode). It physically separates the hydrogen side from the oxygen side. In simple terms, it’s PEM’s job to keep ions moving and gases from mixing. And because PEM operates in an acidic environment, corrosion-resistant components, like titanium and platinum-coated titanium PTLs, must be used.

Early concepts to solid innovation

The story of PEM’s development began in the mid-20th century, when researchers began exploring different ways to convert chemical energy into electricity – using fuel cells. Early systems relied on liquid electrolytes, which created challenges such as leakage, corrosion, and complex balance, to name a few. These limitations motivated the search for solid electrolytes that could conduct protons while remaining mechanically robust.