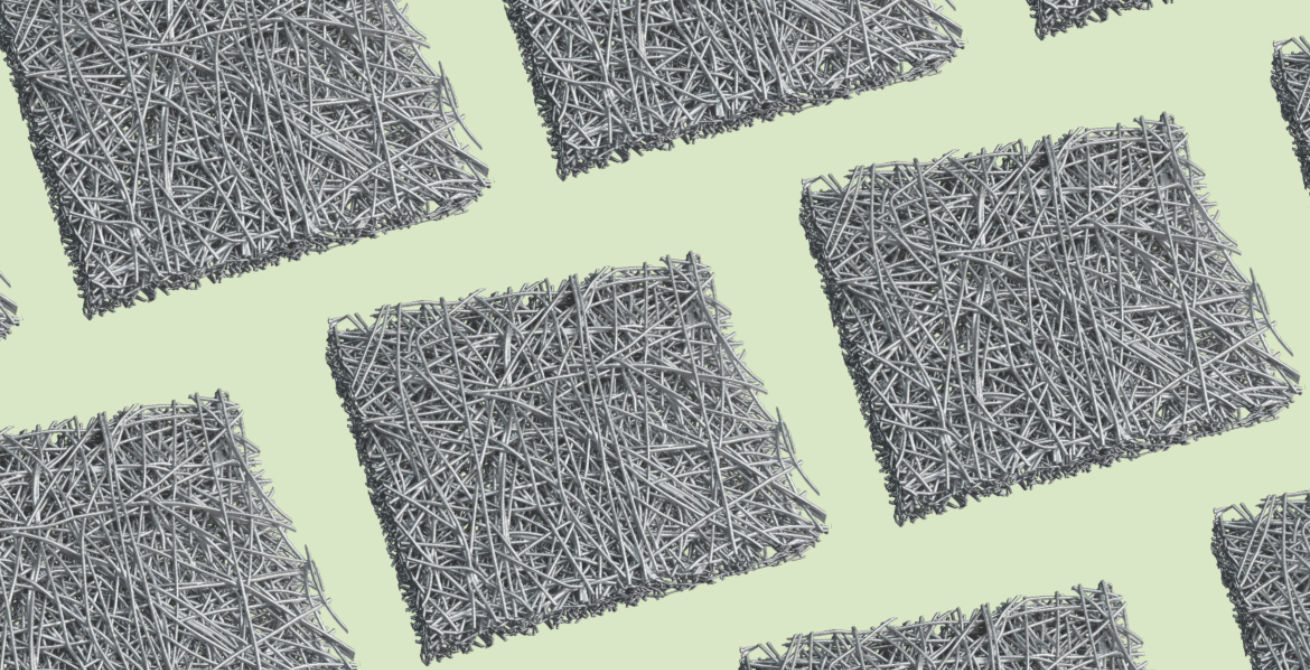

The path to sustainable energy just took a bold leap forward. We have officially opened the doors to the Bekaert Hydrogen Innovation Hub, a cutting-edge facility dedicated to accelerating innovation in electrolyzer technologies and porous transport layer (PTL) development.

The launch marks a major milestone in our commitment to shaping a greener, more resilient energy future – together with our partners, customers, and the global hydrogen ecosystem.