Achieving Europe’s ambitious climate goals requires a significant shift from fossil fuels to renewable energy sources. With the EU aiming to cut greenhouse gas emissions by 40% by 2030—and up to 95% by 2050—there is an urgent need for scalable, sustainable energy solutions. Green hydrogen offers a versatile and clean alternative to decarbonise energy-intensive sectors. However, its widespread adoption depends on overcoming cost, durability, efficiency and resource challenges.

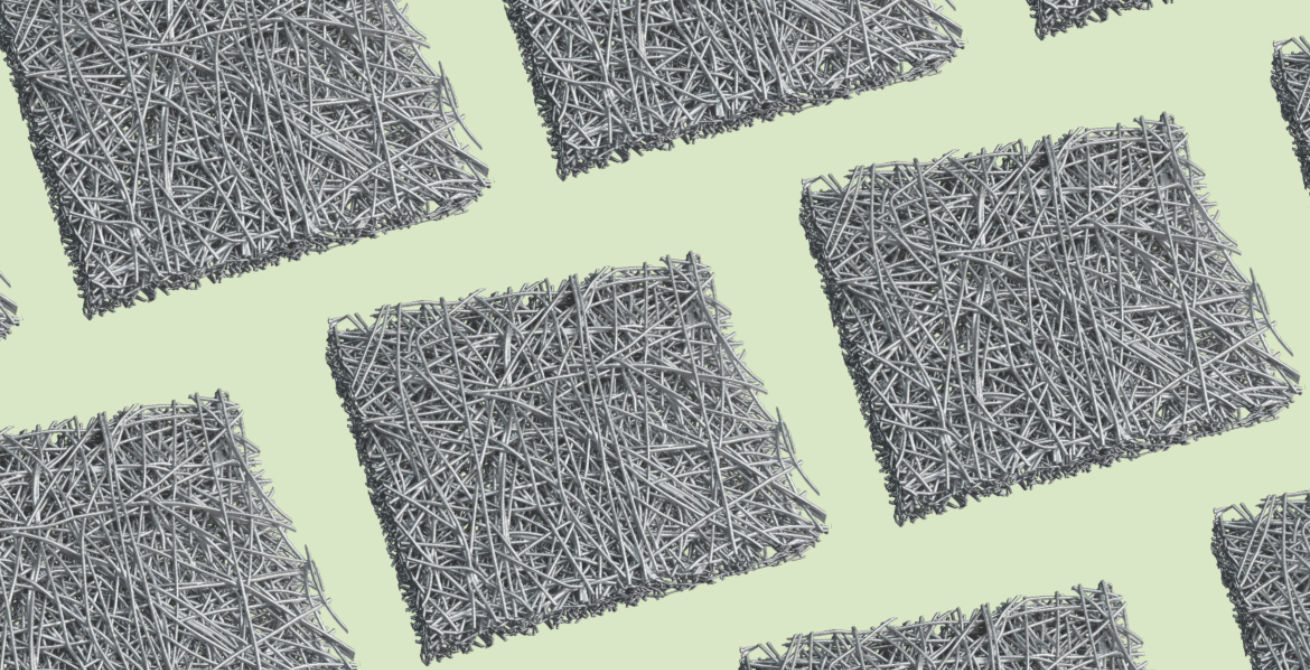

HYScale is addressing this challenge by upscaling innovative high-performance materials that reduce dependency on scarce resources, without compromising on performance or efficiency. By replacing CRMs and PFAS, traditionally used in Anion Exchange Membrane-water electrolyser (AEMEL), the project is advancing the first single stack 100 kW AEM electrolyser prototype, more cost-effective and environmentally friendly for hydrogen production.

Building on a series of tests, the HYScale team has successfully demonstrated that its newly developed materials can be scaled up without compromising performance. Large-scale applications are now delivering results that align with those achieved in small-scale single-cell laboratory tests, a crucial milestone on the path to real-world implementation. With this progress, HYScale is now one step closer to integrating the stack into a fully functional electrolyser system, targeting a CAPEX of 400 €/kW and advancing towards validation in an industrially relevant environment, reaching Technology Readiness Level 5.