The electrolyzer market continues to evolve with the hydrogen industry. From a supplier of high-cost equipment for narrow industrial applications, the sector’s key metrics now involve higher volume sales, a broader customer base, longer operating lifetimes, and – most of all – falling unit costs. All driven by the global energy transition towards clean hydrogen production as both fuel and feedstock.

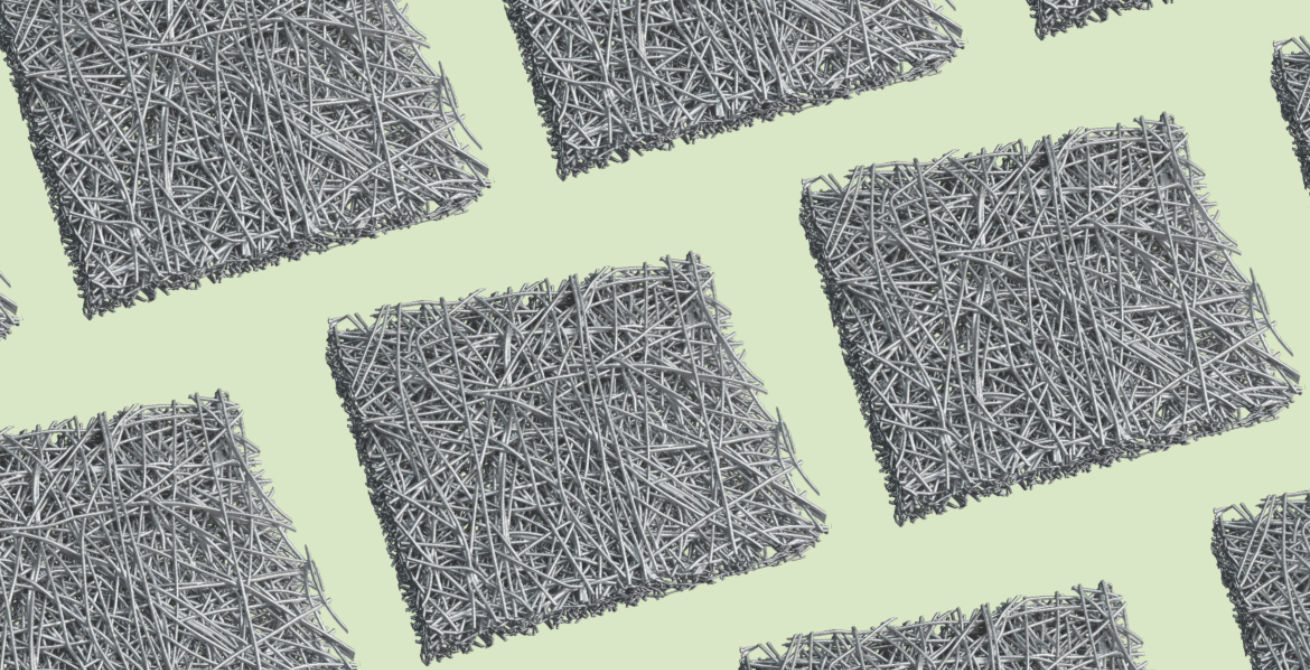

Of course, with change comes challenges. PEM electrolyzers operate under harsh conditions demanding of highly durable Porous Transport Layers (PTLs). These are often made of titanium, an effective but costly material. And while platinum coatings can improve performance and lifetime, they add to the expense. In AEM electrolyzers, research is exploring materials such as nickel and stainless steel to find the right balance of robustness, scalability, and cost.