Nickel is no stranger to electrochemical applications. In the world of hydrogen production, nickel has proven to be an efficient, durable component material. This is particularly true in terms of Anion Exchange Membrane (AEM) electrolyzers.Nickel felt, with its inherent characteristics of conductivity, corrosion resistance, and structural flexibility, serves as a strong option for Porous Transport Layers (PTLs) in corrosive environments. But how does this material fit within the evolving landscape of AEM, and what role will it play in hybrid electrolyzer designs of the future?

AEM electrolyzers bridge the gap between PEM (Porous Exchange Membrane) efficiency and alkaline affordability. Their ability to run on lower-cost materials — including nickel — opens a path to more scalable, economically viable green hydrogen production. As developers aim to cut system costs without compromising performance, AEM has become a key technology to watch.

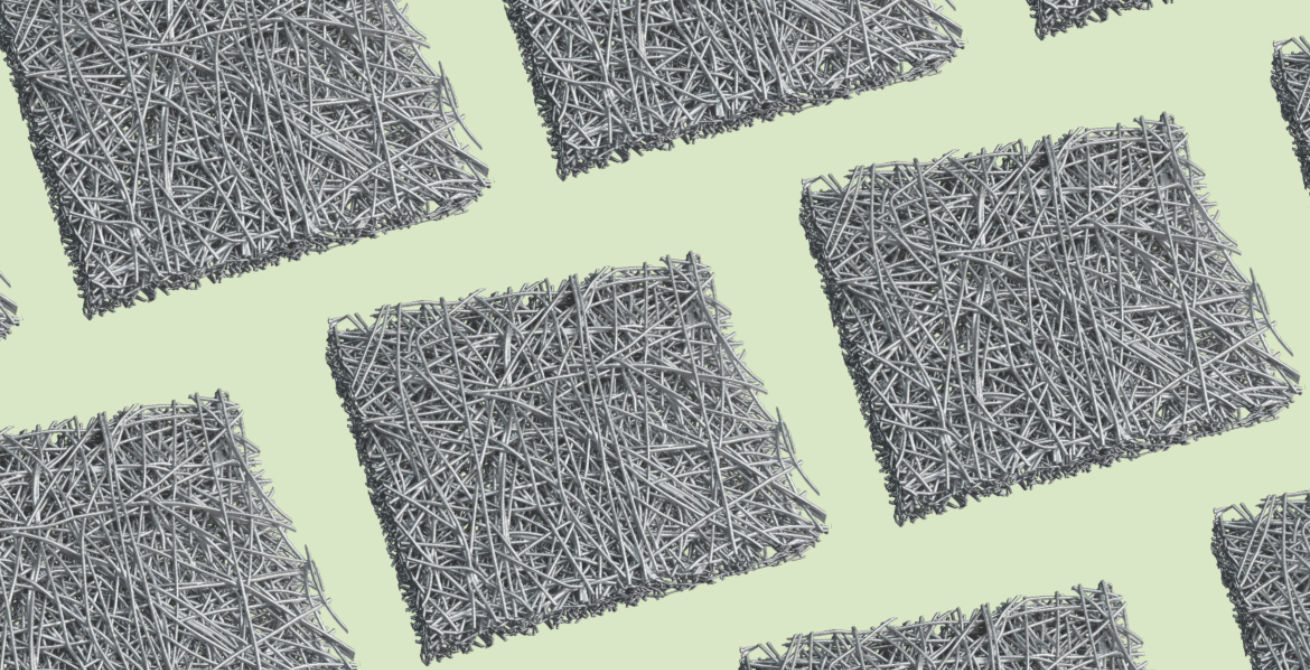

Nestled between the catalyst layer and the flow field, the PTL enables the transport of electrons while facilitating the distribution and removal of gases. It’s here where nickel excels. Its high electrical conductivity minimizes resistance, while its 3D fibrous structure offers a large contact area that reduces energy losses. That same porous, flexible network also provides the mechanical support necessary to maintain compression and constant contact between components, while the strong corrosion resistance under alkaline media ensures its durability. With efficient water access, rapid gas evacuation, and enhanced electrochemically active sites, nickel felt

- Improves hydrogen production rates

- Prevents performance-limiting blockages

- Boost overall stack reliability